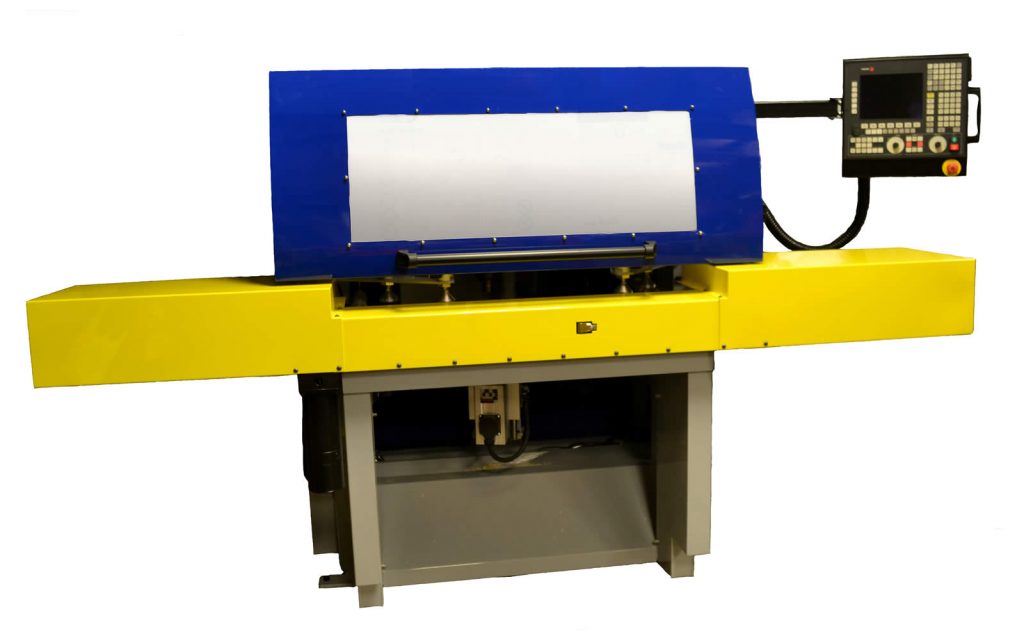

CSR-750CNC Automatic CNC Stair Router

General Information

To make the operation of this machine as easy as possible for use by operators of any skill level the CNC unit is preprogrammed for most stair routing application. However, the CSR-750CNC still retains full capability of programming using standard CNC codes.

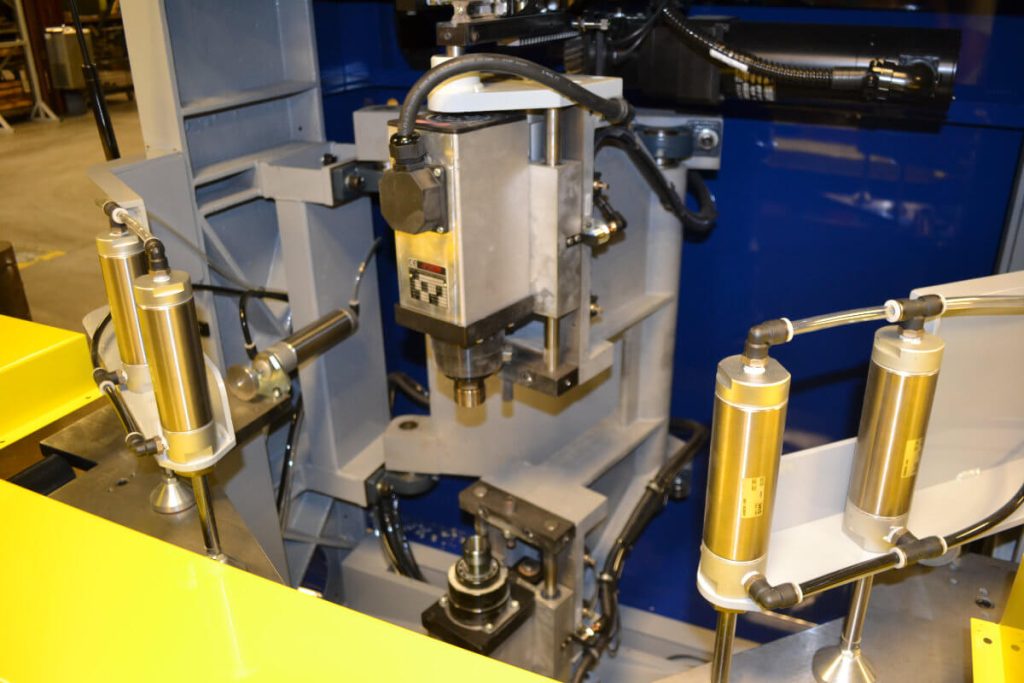

All the operator has to do is simply pick the stair style, enter the rise, run and number of stairs, insert the pair of boards and press the Start button. As the machine takes over, two high speed router motors simultaneously rout both left and right hand stringer with dovetail bit. As a bonus, machine is capable of cutting the open horse stringer and open stringer with 45° riser relief.

Machine Details

- Heavy Duty construction with Cast iron arms and walls

- FAGOR CNC 8055i/A 3-axes package

- Standard programs are:

- Standard Box Step with Round Nose

- Blunt Nose with Rake or Straight Riser

- Open Pan Rout with partial Riser or no Riser

- Temporary Stair Rout

- Center Open Horse Cut

- Open Stringer cut with 45° Riser relief

- Two 5HP High speed router motors

- Two adjustable speed drive controllers

- Automatic board advance every cycle

- Networking, and remote data entry and supervision

- Max material width 12″

- Material thickness: ¾” – 3-1/2″

- Tool shank capacity ¾”

- Max. feed speed 300 FPM

- Communication ports: RS232, USB, network

- Machine dimensions 94″L x 60″D x 64″H

- Weight approx. 4200 lbs

- Dust outlet 8″